Build a cheap turbofan: Difference between revisions

design part adding |

→Shaped core or shaped shaft?: image crafted shaft |

||

| Line 27: | Line 27: | ||

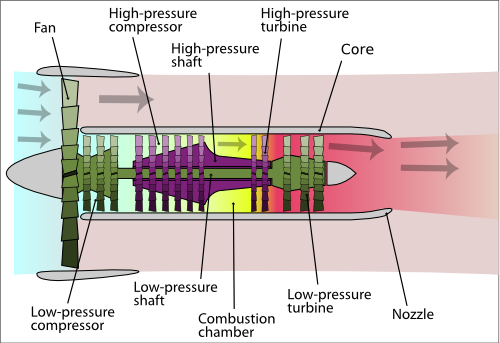

I think that the main thing that can be optimized to reduce cost and complexity is the design of the compression areas. In the above picture, we see that the shaft is straight and that the core enveloppe is curved to reduce volume on the high compression stage. In practice, the shaft has a bumped profile (small-large-small diameter), to help reduce the volume. | I think that the main thing that can be optimized to reduce cost and complexity is the design of the compression areas. In the above picture, we see that the shaft is straight and that the core enveloppe is curved to reduce volume on the high compression stage. In practice, the shaft has a bumped profile (small-large-small diameter), to help reduce the volume. | ||

[[Image:500px-Turbofan_craftedshaft.svg.png]] | |||

===Compressor and turbine blades=== | ===Compressor and turbine blades=== | ||

Revision as of 17:48, 29 January 2010

How to build a cheap (~ $150) turbofan?

Turbofan advantages over other propelling ways is that they provide enough trust to climb at high altitude, possibly at attractive speed, and that they are not much fuel-greedy and thus can be running for some time with limited extra-weight.

It however has the big disadvantage to be very complicated to manufacture as well as very expensive. On this page, we will explore how costs can be reduced, which will be the key for decision to use turbofans or not. They will have to be build in some way, because it will have to be tailored to our needs, which are quite unusual.

General principes

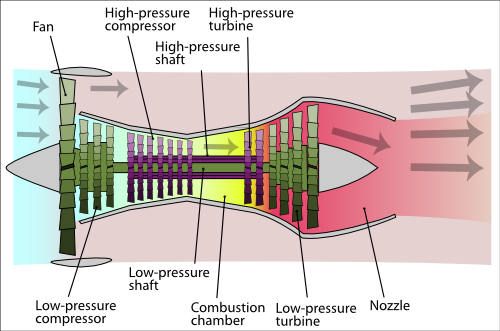

Lots of information are available on wikipedia's page. General principe is that there is a combustion that feeds a turbine, which drives the fan and the compression stage. The fan provides thrust from creating air pressure, and the combustion create thrust by evacuating hot gaz. As air is compressed from the intake, more air becomes available for combustion, and thus create more work on the turbine, and more intake. It is often seen that a second concentrical shaft for high pressure operations drives the low pressure shaft on which is mounted the fan.

There are some design properties and configurations that have to be properly calculated depending on the use of the engine, mainly for the intented aircraft speed:

- The Bypass ratio (BPR) is a ratio between the mass flow rate of air drawn in by the fan but bypassing the engine core to the mass flow rate passing through the engine core. A BPR = 0 would be a turbojet engine. The higher BPR, the more efficient the engine, but also the slower exhaust speed.

Turbojet/turbofan engine simulation software from NASA: EngineSim

Design versus manufacturing

Design configurations and properties on real engines tend to increase efficiency, meaning higher thrusts for lower fuel consumption, but also try to reduce the exhaust noise. Cost is of course a concern, and an efficiency by itself, but not a constraint as important as it is for us.

Shaped core or shaped shaft?

I think that the main thing that can be optimized to reduce cost and complexity is the design of the compression areas. In the above picture, we see that the shaft is straight and that the core enveloppe is curved to reduce volume on the high compression stage. In practice, the shaft has a bumped profile (small-large-small diameter), to help reduce the volume.

Compressor and turbine blades

Turbofan blades are made of nickel-based superalloys.

Our design

Cooling might be needed if low cost metals are used.

Startup can be done at ground manually (with compressed air for example).

Engine must be designed with sensors, at least to determine if the engine is running properly or if it's under failure. Engine temperature should be used too.

External hardware

Fuel tanks in the wings, fuel pumps, fuel lines, and engine mounting will have to be considered if turbofans are used.