Turbofan:Combustors: Difference between revisions

→Our design: sketch of the combustor |

→Typical designs: text fixes |

||

| Line 7: | Line 7: | ||

The basic principle is that the combustor takes the compressor discharge flow, which has a high velocity, a high pressure, and a high enough temperature for the combustion to occur with a reduced risk of flaming-out. The first job of the combustor is to slow down the flow so that it can be mixed to fuel and provide a stable flame. The second task of the combustor is to prevent the flame from spreading outside it, and thus preventing a too hot flow to spread on other parts of the engine. Its design ensures that the flame will be properly confined, and that the output gas temperature will be acceptable for the turbine. The hotter the gas is discharged in the turbine, the more energy will be gained from the combustion. To limit this temperature, and also to limit the combustor temperature to avoid its own melting down, diluting air is introduced in the combustor. | The basic principle is that the combustor takes the compressor discharge flow, which has a high velocity, a high pressure, and a high enough temperature for the combustion to occur with a reduced risk of flaming-out. The first job of the combustor is to slow down the flow so that it can be mixed to fuel and provide a stable flame. The second task of the combustor is to prevent the flame from spreading outside it, and thus preventing a too hot flow to spread on other parts of the engine. Its design ensures that the flame will be properly confined, and that the output gas temperature will be acceptable for the turbine. The hotter the gas is discharged in the turbine, the more energy will be gained from the combustion. To limit this temperature, and also to limit the combustor temperature to avoid its own melting down, diluting air is introduced in the combustor. | ||

A can combustor features mechanisms | A can combustor features all mechanisms required for a proper combustion: input air flow slow down, fuel injection nozzles, air dilution flows, and a hot gas discharge. Several cans are then placed circumferentially in the engine's core. The main drawback is the loss of useful volume in the combustor section, and the non-uniformity of the hot gas discharge. | ||

The can-annular combustor has a single air dilution diffuser for all combustion cans, | The can-annular combustor has removed the external shell of cans, allowing a single air dilution diffuser to exist for all combustion cans, which is actually the core's shell itself. They make more efficient use of the volume and reducing the design complexity and weight. | ||

Finally, annular combustors are designed as a single annular part taking the | Finally, annular combustors are designed as a single annular part taking all the available volume from the combustion section. All modern engines use this design, so do we. | ||

==Combustor properties== | ==Combustor properties== | ||

Revision as of 23:41, 3 November 2011

Turbofan combustor

Typical designs

A good summary can be found at chapter 5 of the book "Jet engines: fundamentals of theory, design, and operation". We summarize it even more here. Three main designs exist: can combustors, can-annular combustor, and annular combustor. They were invented in that order, to solve some of the flaws of previous models.

The basic principle is that the combustor takes the compressor discharge flow, which has a high velocity, a high pressure, and a high enough temperature for the combustion to occur with a reduced risk of flaming-out. The first job of the combustor is to slow down the flow so that it can be mixed to fuel and provide a stable flame. The second task of the combustor is to prevent the flame from spreading outside it, and thus preventing a too hot flow to spread on other parts of the engine. Its design ensures that the flame will be properly confined, and that the output gas temperature will be acceptable for the turbine. The hotter the gas is discharged in the turbine, the more energy will be gained from the combustion. To limit this temperature, and also to limit the combustor temperature to avoid its own melting down, diluting air is introduced in the combustor.

A can combustor features all mechanisms required for a proper combustion: input air flow slow down, fuel injection nozzles, air dilution flows, and a hot gas discharge. Several cans are then placed circumferentially in the engine's core. The main drawback is the loss of useful volume in the combustor section, and the non-uniformity of the hot gas discharge.

The can-annular combustor has removed the external shell of cans, allowing a single air dilution diffuser to exist for all combustion cans, which is actually the core's shell itself. They make more efficient use of the volume and reducing the design complexity and weight.

Finally, annular combustors are designed as a single annular part taking all the available volume from the combustion section. All modern engines use this design, so do we.

Combustor properties

Combustor, like other parts of the engine, operate with air flow. It thus affects its properties, like temperature, pressure and velocity. A combustor is said efficient when it minimizes the pressure drop. The air used for combustion must be slowed down, and this is generally done by both expanding the input flow and swirling a part of it. This swirl causes turbulences that imply pressure loss, and thus efficiency reduction of the combustor.

The produced hot gas will be used to provide energy to the engine, and this energy needs to be in an easily extractable form. High temperatures and high velocities are appreciable for turbine work extraction. There is probably no upper bound for velocity, but there is one for temperature, the temperature that the turbine inlet vanes can sustain, and the temperature that the turbine blades can sustain.

Our design

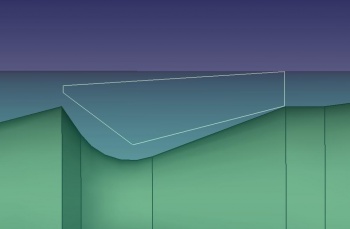

The following sketch represents the position and the shape of the combustor on the shaft (below in green) and the core's shell (above and in the front of the picture with transparency). All air will be forced into the combustor, mainly at the middle and the rear part of it to dilute the hot gas. Its section increases at front, to allow burning to happen, and decreases at rear, which will speed up and cool down exit gases too.

TODO: Flame holding, Cooling, Material, Ignition.